Bottleneck

6 Slides

6 Slides

File size: 16:9

File size: 16:9

Fonts: Lato Black, Calibri

Fonts: Lato Black, Calibri  Supported version

PPT 2010, PPT 2013, PPT 2016

Supported version

PPT 2010, PPT 2013, PPT 2016

Product details

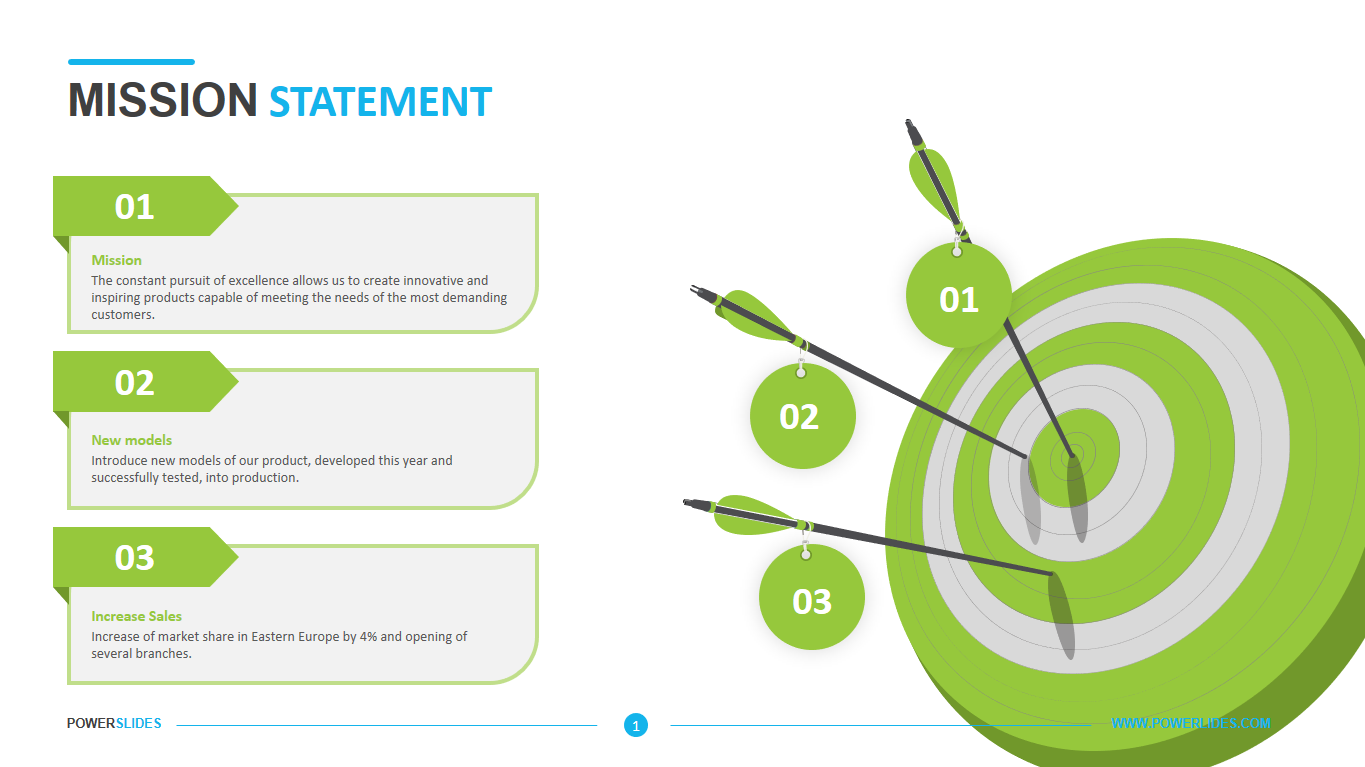

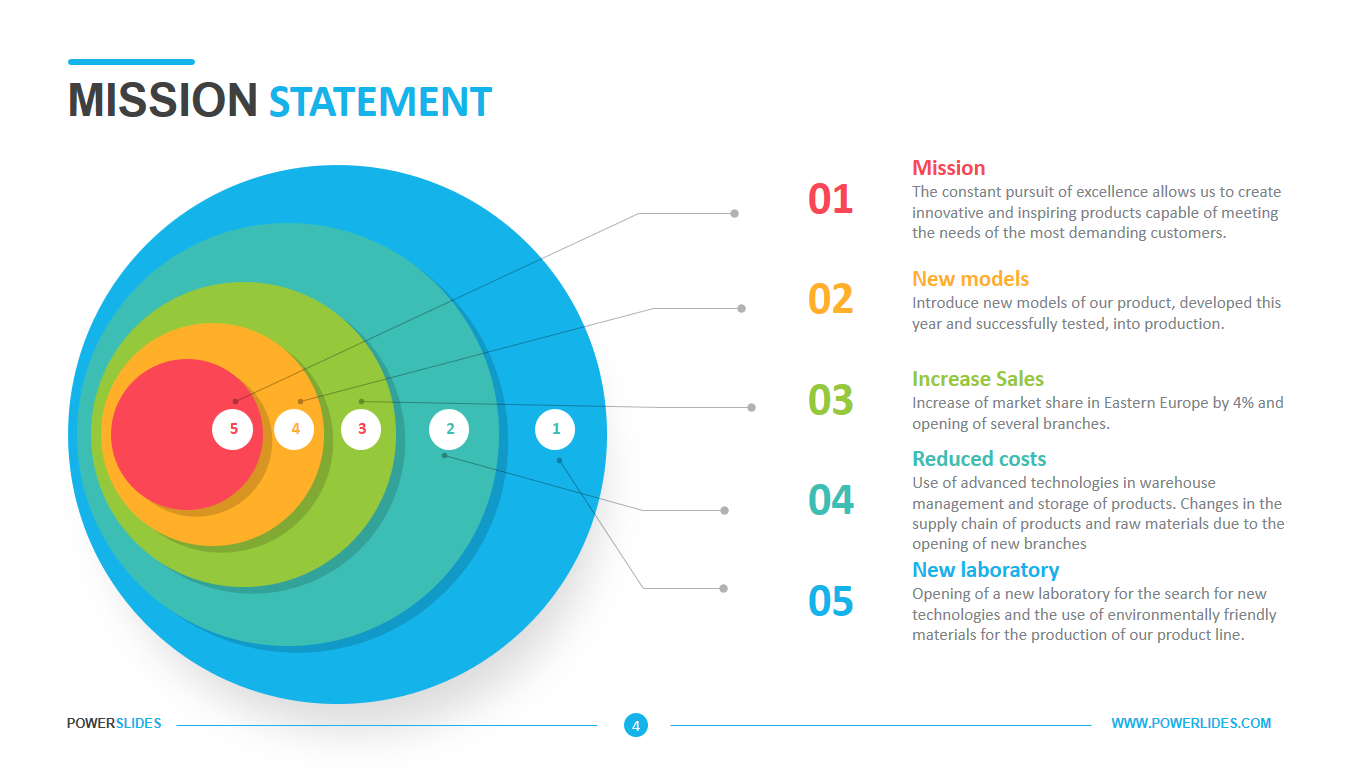

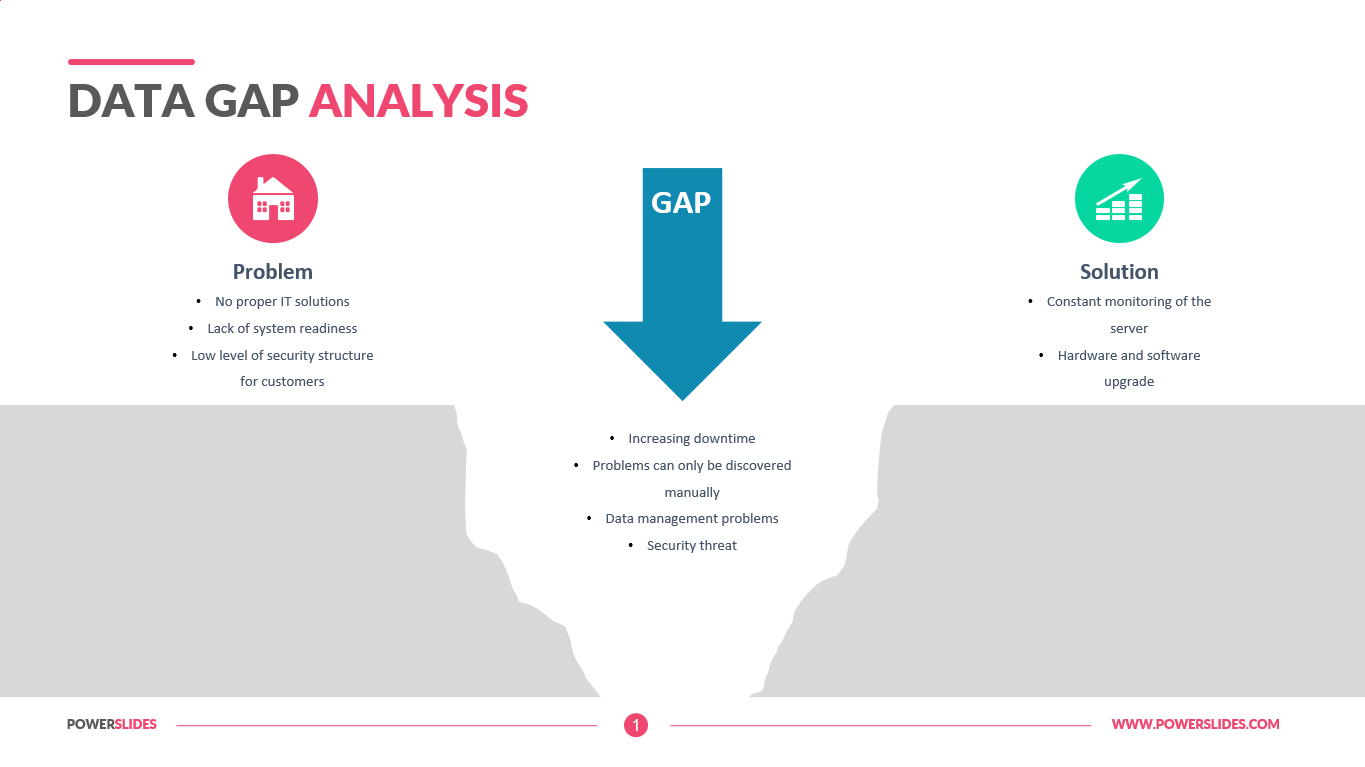

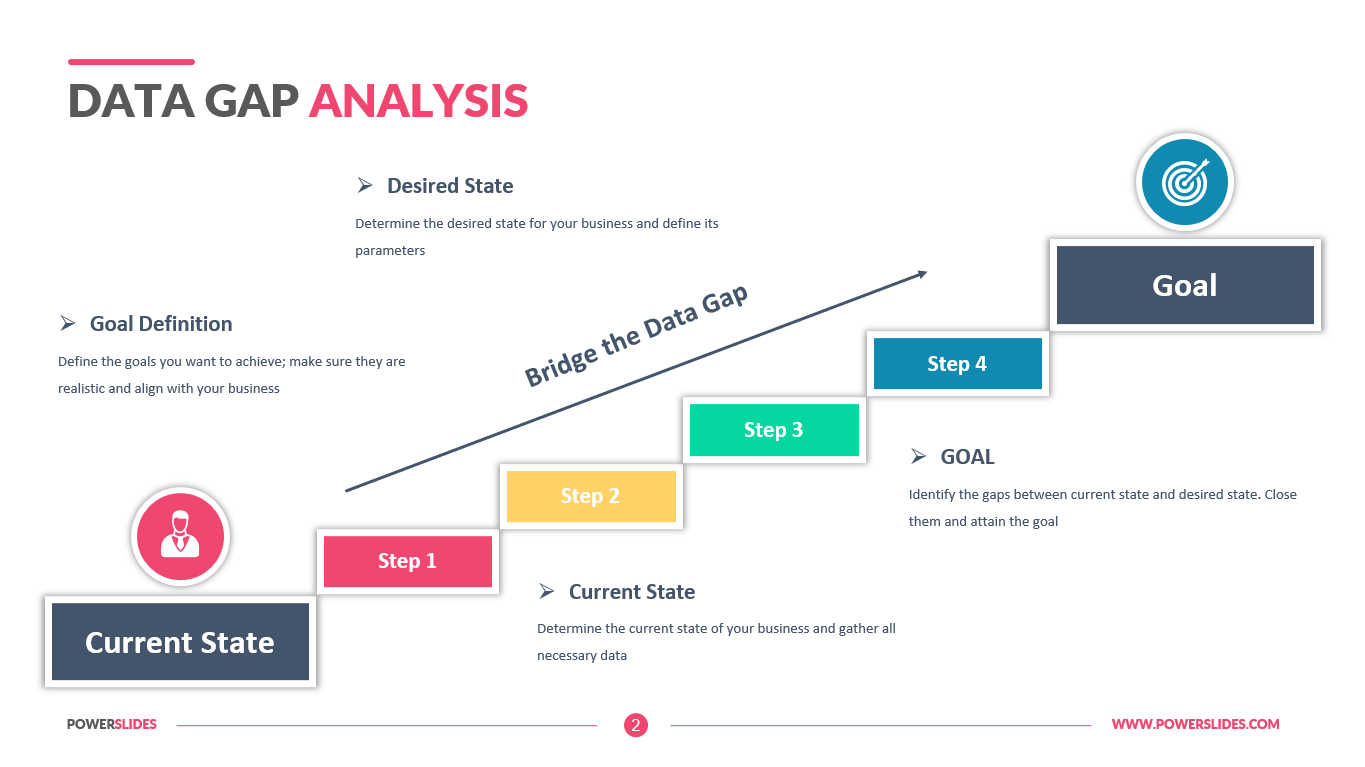

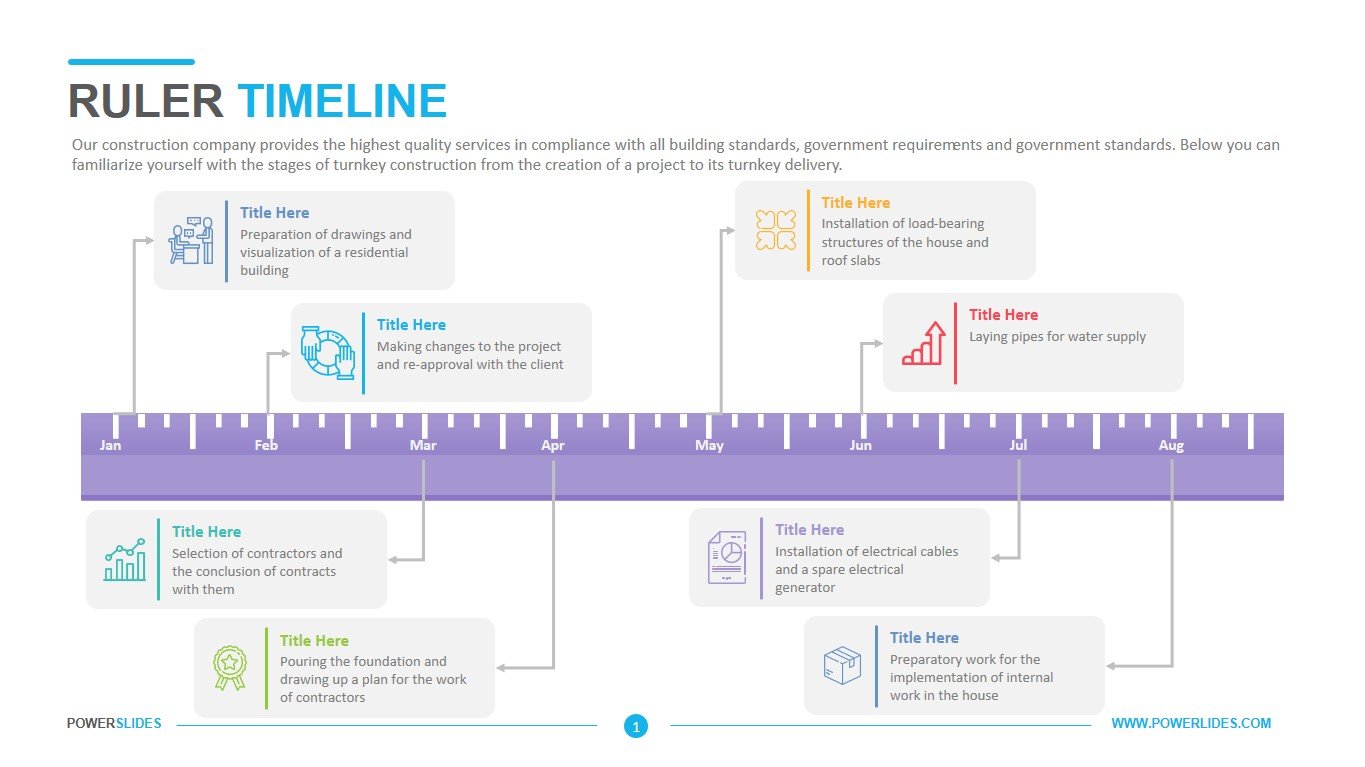

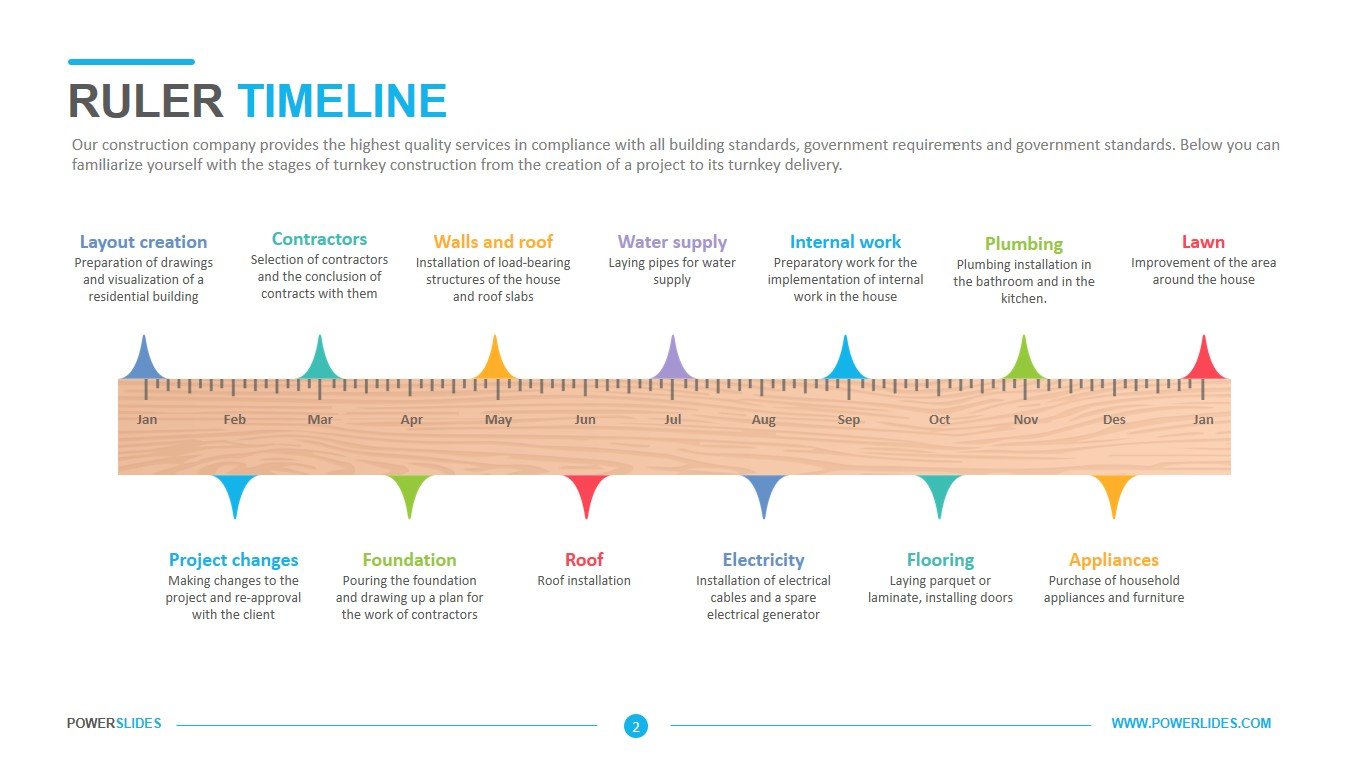

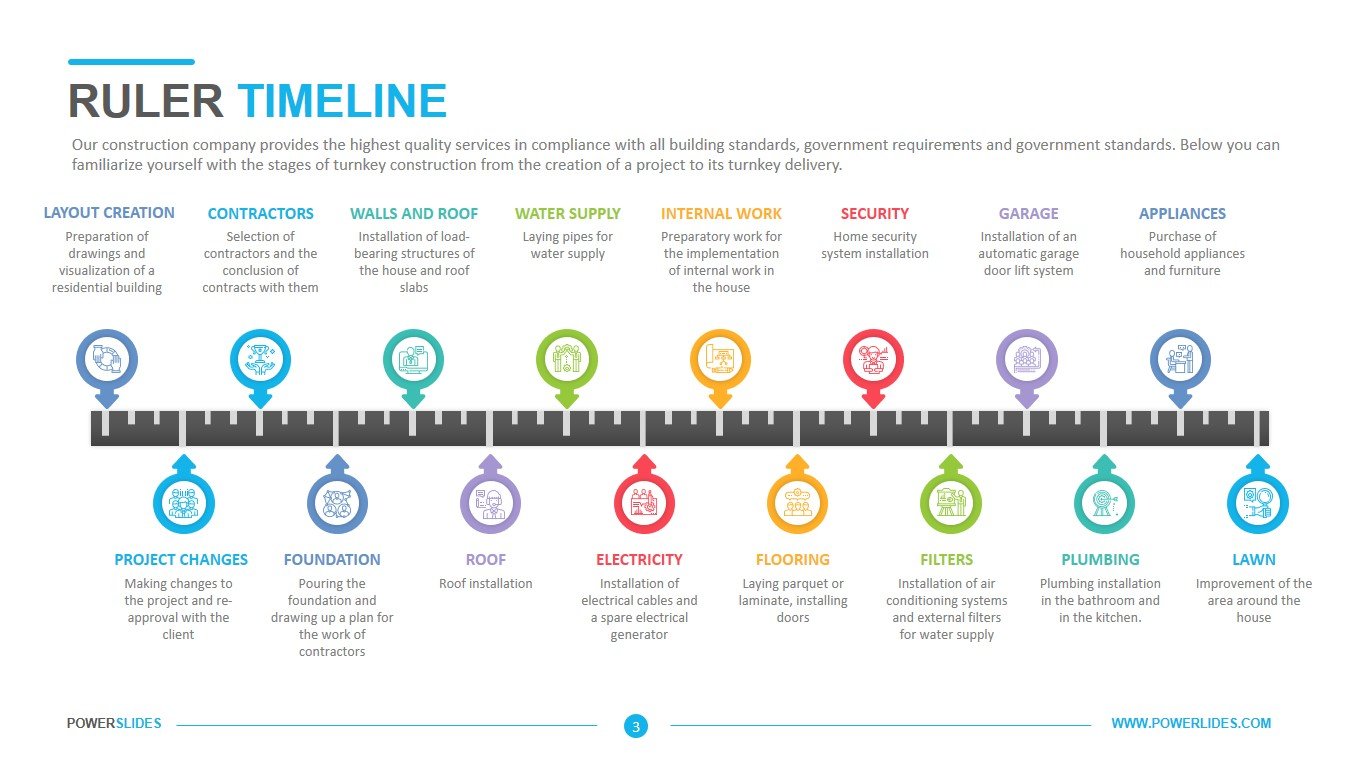

A bottleneck is a point of congestion in a production system such as a manufacturing assembly line or a computer network that occurs when workloads arrive too quickly for the production process to handle. The inefficiencies brought about by the bottleneck often creates delays and higher production costs in the supply chain, which is well conceptualized in these horizontal funnel diagrams.

A bottleneck can have a significant impact on the flow of manufacturing and can sharply increase the time and expense of production. Companies are more at risk for bottlenecks when they start the production process for a new product. This is because there may be flaws in the process that the company must identify and correct; this situation requires more scrutiny and fine-tuning. Operations management is concerned with controlling the production process, identifying potential bottlenecks before they occur, and finding efficient solutions.

A bottleneck affects the level of production capacity that a firm can achieve each month. Theoretical capacity assumes that a company can produce at maximum capacity at all times.

Because theoretical capacity is not realistic, most businesses use practical capacity to manage production. This level of capacity assumes downtime for machine repairs and employee time off. Practical capacity provides a range for which different processes can operate efficiently without breaking down. Go above the optimum range and the risk increases for a bottleneck due to a breakdown of one or more processes.

A variance in the production process is the difference between budgeted and actual results. Managers analyze variances to make changes, including changes to remove bottlenecks. If actual labor costs are much higher than budgeted amounts, the manager may determine that a bottleneck is delaying production and wasting labor hours. If management can remove the bottleneck, labor costs can be reduced.

A bottleneck can also cause a material variance if materials are exposed to spoilage or possible damage as they sit on the factory floor waiting to be used in production. Bottlenecks may be resolved by increasing capacity utilization, finding new suppliers, automating labor processes, and creating better forecasts for consumer demand.

This template will be useful for engineers and production line managers. You can use this template when designing production lines or upgrading production. You can describe in detail what activities you plan to carry out in order to avoid bottleneck risks.

Crisis managers can use the slides in this template when preparing a company’s recovery strategy. You can describe in detail the weaknesses of the company and suggest ways to bring the company out of losses. University professors can use this template when preparing courses on efficient manufacturing or building efficient business processes.

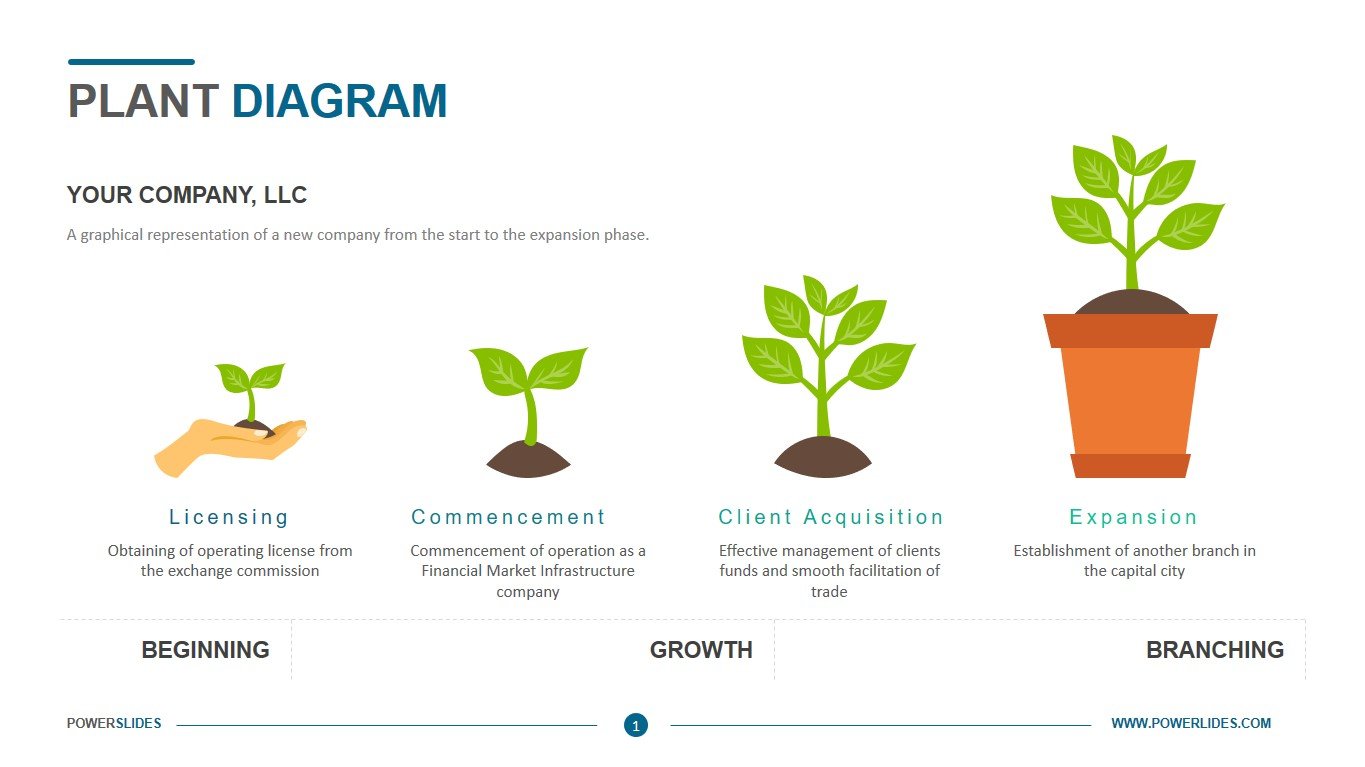

This collection of Bottleneck slides is a professional and modern template pack that contains six stylish and fully editable slides. You can change the type and size of the font, color and position of the infographic yourself. This template will be useful for project managers, crisis managers, startup leaders. Bottleneck template will complement your old presentations and will be a worthy addition to your collection of professional presentations.

(4.00/ 5)

(4.00/ 5)